Use

Use

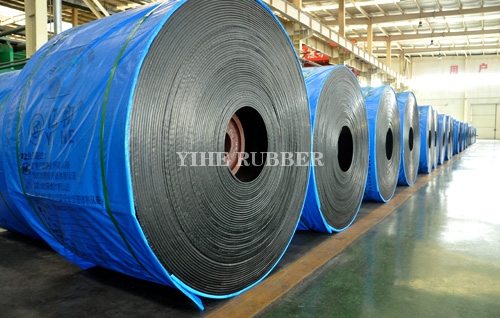

Used in coal, mining, port, metallurgy, electric power, chemical industry in areas such as conveying material.

Characteristics

Characteristics

1、High tensile strength 2、good impact resistance 3、long service life 4、Small elongation 5、Good grooved-formed performance 6、Good flexibility

Structure

Structure

Take consists of cover glue, glue, glue side middle longitudinal spacing according to certainarranged of wire rope.

ST series wire rope core belt main technical parameters(Each general)

Belttype | 500 | 630 | 800 | 1000 | 1250 | 1400 | 1600 | 1800 | 2000 | 2250 | 2500 | 2800 | 3150 | 3500 | |

The minimum tensile strength KNmin(N/mm) | 500 | 630 | 800 | 1000 | 1250 | 1400 | 1600 | 1800 | 2000 | 2250 | 2500 | 2800 | 3150 | 3500 | |

A maximum diameter of wire rope dmax(mm) | 3.0 | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 5.0 | 5.6 | 6.0 | 5.6 | 7.2 | 7.2 | 8.1 | 8.6 | |

Wire rope minimum tensile force Fbs minkN | 7.6 | 7.0 | 8.9 | 12.5 | 16.1 | 20.6 | 20.6 | 25.5 | 25.6 | 26.2 | 40.0 | 39.6 | 50.5 | 56.0 | |

Wire rope spacing t(mm) | 14.0 | 10.0 | 10.0 | 12.0 | 12.0 | 14.0 | 12.0 | 13.5 | 12.0 | 11.0 | 15.0 | 13.5 | 15.0 | 15.0 | |

Minimum thickness of covering layer Smin(mm) | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 5.0 | 5.0 | 5.5 | 6.0 | |

Bandwidth(mm) | Limitdeviation(mm) |

Number of wire ropes | |||||||||||||

800 | +10/-8 | 54 | 75 | 75 | 63 | 63 | 55 | 63 | 57 | 63 | 69 | 50 | 57 | 50 | 50 |

| 1000 | ±10 | 68 | 95 | 95 | 79 | 79 | 68 | 79 | 71 | 79 | 89 | 64 | 71 | 64 | 64 |

| 1200 | ±10 | 83 | 113 | 113 | 94 | 94 | 82 | 94 | 85 | 94 | 104 | 76 | 85 | 76 | 77 |

| 1400 | ±12 | 96 | 113 | 113 | 111 | 111 | 97 | 111 | 100 | 111 | 122 | 89 | 99 | 89 | 90 |

| 1600 | ±12 | 111 | 151 | 151 | 126 | 126 | 111 | 126 | 114 | 126 | 140 | 101 | 114 | 101 | 104 |

| 1800 | ±14 | 125 | 171 | 171 | 143 | 143 | 125 | 143 | 129 | 143 | 159 | 114 | 128 | 114 | 117 |

| 2000 | ±14 | 139 | 191 | 191 | 159 | 159 | 139 | 159 | 144 | 159 | 177 | 128 | 143 | 128 | 130 |

2200 | ±15 | 153 | 211 | 211 | 176 | 176 | 154 | 176 | 159 | 176 | 195 | 141 | 158 | 141 | 144 |

Flame retardant series wire rope core belt main teachnical parameters

Cover thickness of flame retardant tape

| Model | ST/S630 | ST/S800 | ST/S1000 | ST/S1250 | ST/S1600 | ST/S2000 | ST/S2500 | ST/S2800 | ST/S3150 |

Thickness of top rubber cover≥ | 5.0 | 5.0 | 6.0 | 6.0 | 6.0 | 8.0 | 8.0 | 8.0 | 8.0 |

Thickness of bottom rubber cover≥ | 5.0 | 5.0 | 6.0 | 6.0 | 6.0 | 8.0 | 8.0 | 8.0 | 8.0 |

| Model | ST/S630 | ST/S4000 | ST/S4500 | ST/S5000 | ST/S5400 | ST/S6300 | ST/S7000 | ST/S7500 | |

Thickness of top rubber cover≥ | 8.0 | 8.0 | 8.0 | 8.5 | 9.0 | 10.0 | 10.0 | 10.0 | |

Thickness of bottom rubber cover≥ | 8.0 | 8.0 | 8.0 | 8.5 | 9.0 | 10.0 | 10.0 | 10.0 |

The steel wire rope core flame-retardant conveyor belt (used in coal mines) implements the MT668 standard, and the covering rubber performance is as follows

Covering the adhesive performance | Tensile Strength(Mpa)≥ | 15 | |||

| Elongation at break(%)≥ | 350 | ||||

| After aging test (700Cx168h) | Tensile strength change rate(%) | ±25% | |||

| Change rate of elongation at break(%) | ±25% | ||||

| Abrasion(mm3) | 200 | ||||

| hardness(SH0A) | 70±5 | ||||

Flame-retardant antistatic property | Drum blowtorch burning test | When each specimen is subjected to the roller friction test | The sample has no open flame or flameless combustion | ||

| Roller surface temperature ℃,≤ | 325 | ||||

| Burning test of alcohol blowtorch | Specimen with complete covering | Flaming | The average self-extinguishing time of 6 samples is not more than 3 seconds | ||

| The single value of any sample is not more than 10 seconds | |||||

| Flameless combustion | The average self-extinguishing time of 6 samples is not more than 3 seconds | ||||

| The single value of any sample is not more than 10 seconds | |||||

| Strip the cover test piece | Flaming | The average self-extinguishing time of 6 samples is not more than 3 seconds | |||

| The single value of any sample is not more than 10 seconds | |||||

| Flameless combustion | The average self-extinguishing time of 6 samples is not more than 3 seconds | ||||

| The single value of any sample is not more than 10 seconds | |||||

| Roadway propane combustion test | Full width unburnt length,mm≥ | 600 | |||

| Surface resistance value | Average surface resistance of the upper and lower sides Ω≤ | 3x108 | |||